|

Why CertoClav EL sterilizer?

Compact: benchtop autoclave located directly at the laboratory workplace. Fast: short cycle times thanks to direct heating Practical: always processing the right quantity. No waiting for the big autoclaves Reliable: often more than 20 years in use. Lifelong service

|

|

{slider=Technical capability} - Power output: selectable between 125°/140°C. Special valve 115°/121°C available (0.7 - 2.7 bar / 10.2 - 39.2 psi overpressure). Solution of culture media (Agar) at 100°C

- Venting: venting using flow process. Steam saturation: non-condensable gases <3% (as mandated in EN 13060)

- Sterilisation material: solid instruments, liquids (culture media) bottles and devices, waste sterilisation

- Size, loading: optimal usage of chamber volume thanks to loading from above. Even long instruments up to 42 cm (18 L version) can be processed {/slider}

|

|

Why CertoClav MultiControl sterilizer?

Flexible: Use in sterilisation, materials testing and research. Fractioned ventilation. Long-term cycles are easy to implement. Standard tests such as ICP-TM 650, GB-AL 631, HAST Test and Pressure Vessel Test can be carried out. Practical: automatic process control and monitoring saves valuable employee time Safe: independent error detection and data connection guarantee the sterilisation result. Reliable: control system and device in industrial quality

|

|

- Venting: Venting using fractioned flow process. Steam saturation: non-condensable gases 3% (as required by EN 13060)

- Autoclave items: solid instruments, liquids (culture media), bottles and devices, waste sterilisation. Any durable material for material tests and research. Acids can be autoclaved but do, however, lead to corrosion in the autoclave in the medium-term.

- Size, loading: optimal usage of chamber volume thanks to loading from above. Even long instruments up to 42 cm (18 L version) can be processed

- Multiple systems: The 4-stage CertoSecure safety system consists of an excess pressure valve, pressure valve, safety cover locking device against opening to pressure and overpressure safety recess.

- Safe operation: the CertoLock lock closes safely with just one easy step. No need for time-consuming screwing as with other makes.

Instruments: precision manometer with drag pointer, electronic temperature display. LCD display for process progress and process parameters. Data interface.

Connections: No additional water connection required. Electrics: 220V, 50-60Hz, 1900 W. Data interface RS 232 and 10mV

Standards: complies with international standards. GS mark in accordance with DIN and VDE/IEC (EN61010:1:2001 and 61010:2:040:2005). CE-conform.

Heater: integrated in base. Heating elements are not in contact with water, therefore extended service life.

|

|

|

|

|

|

The ELF laboratory furnaces comprise 3 bench mounted models designed for light duty and general use up to 1100 °C. These laboratory furnaces have a simple drop down door and a top mounted ceramic chimney. The combination of low thermal mass insulation and free radiating wire elements embedded in the chamber sides provide efficient heating.

|

|

- 1100°C maximum operating temperature

- 6, 14 or 23 litre chamber volumes

- Drop down door with air gap to minimise external temperature

- Carbolite 301 controller, with single ramp to set-point & process timer

- Delayed start / process timer function as standard

- Vacuum formed, low thermal mass insulation

- Hard ceramic hearth fitted as standard

- Ventilated via top mounted ceramic chimney

- Over-temperature protection (recommended to protect valuable contents & for unattended operation)

Control Options

Please note: - Heat up rate is measured to 100°C below max, using an empty chamber

- Holding power is measured at continuous operating temperature

- External dimensions with door closed and including chimney

- The uniform volume is smaller than the total chamber volume

|

|

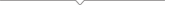

The CWF laboratory chamber furnaces range of general purpose furnaces is supplied in three sizes, each available with a maximum operating temperature of either 1100 °C, 1200 °C or 1300 °C.

|

|

- 1100°C, 1200°C or 1300°C maximum operating temperature

- 5, 13 or 23 litre chamber volumes

- Up & away door keeps heated surface away from the user

- Carbolite 301 controller, with single ramp to set-point & process timer

- Delayed start / process timer function as standard

- Hard wearing alumina element carrier, furnace entrance and hearth

- Energy efficient low thermal mass insulation

- Free radiating wire wound elements pitched for optimum uniformity

- Easy access to elements & controls simplifies maintenance & servicing

- Over-temperature protection (recommended to protect valuable contents & for unattended operation)

- A range of sophisticated digital controllers, multi-segment programmers and data loggers is available. These can be fitted with RS232, RS485 or Ethernet communications

- A variety of retorts & modifications are available for working with modified atmospheres

Control Options - 3508 Programmable Controllers

Please note: - Heat up rate is measured to 100°C below max, using an empty chamber

- Holding power is measured at continuous operating temperature

- Maximum power and heat up times based on a 240V supply

- The uniform volume is smaller than the total chamber volume

|

|

The RWF rapid wire chamber furnaces are available in three chamber sizes with maximum operating temperatures of 1100 °C or 1200 °C.

The free radiating wire elements in combination with low thermal mass insulation are designed to provide rapid thermal response within the chamber.

|

|

- 1100°C or 1200°C maximum operating temperature

- 5, 13 or 23 litre chamber volumes

- Ambient to 1000°C in as little as 10 minutes

- Rapid thermal response from free radiating coiled wire elements

- Low thermal mass insulation for high energy efficiency

- Up & away door keeps heated surface away from the user

- Carbolite 301 controller, with single ramp to set-point & process timer

- Hard wearing hearth

- Over-temperature protection (recommended to protect valuable contents & for unattended operation)

- A range of sophisticated digital controllers, multi-segment programmers and data loggers is available. These can be fitted with RS232, RS485 or Ethernet communications

Control Options - nanodac Record / Control / Programmer - 3216 Programmable Controllers - 3508 Programmable Controllers

Please note: - Heat up rate is measured to 100°C below max, using an empty chamber

- Holding power is measured at continuous operating temperature

- Maximum power and heat up times based on a 240V supply

- The uniform volume is smaller than the total chamber volume

|

|

Series POT Used in good experiment environment without much vibration isolation. |

|

- High density Honeycomb core structure The supports (Isolators) adopt compound-material solid damping (vibration-isolating pad), which is used in such experimental environment without much vibration.

|

|

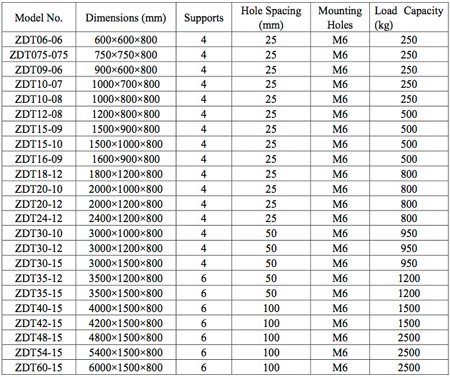

Series ZDT Application: |

|

- High density Honeycomb core structure

The support system (Isolators) adopts the patented technology: Ultra-thin diaphragm air-spring with self-collimating pendulum bar technique, which can provides a relative stationary experiments environment with auto inflating and self-centering performance. The pneumatic system is of Germany FESTO products.

- Height: standard height 800mm or as user preferred. - Self balancing with bulb self-centering pendulum-bar technique. - Re-leveling Accuracy: ±0.250mm - Vertical Isolation, 5Hz: 92% - Horizontal Isolation, 5Hz: 90% - Vertical Isolation, Res: 1Hz - Vertical Isolation, 10Hz: 95% - Horizontal Isolation, Res: 1-2Hz - Auto air inflating system.

|

|

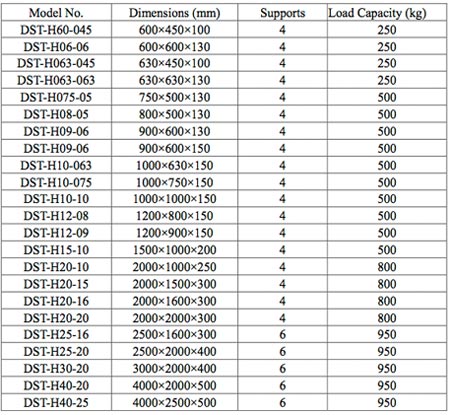

Series DST-H Application: Production Features: |

|

- Specific Gravity : 2970~3070kg/m2

Two kinds of isolators:

1.Pneumatic isolators 2.Solid damping isolators ( Pricelist for the granite table with solid damping isolators)

|

- Tried-and-tested technology: 50 years of experience in autoclave construction

- Tried-and-tested technology: 50 years of experience in autoclave construction Controller: pressure control via valve, temperature control via thermostat.

Controller: pressure control via valve, temperature control via thermostat.

- Power output: freely selectable temperature from room temperature up to 140° C (up to 2.7 bar / 39.2 psi overpressure).

- Power output: freely selectable temperature from room temperature up to 140° C (up to 2.7 bar / 39.2 psi overpressure).